2 1 mamut

Below you can find info about the second generation development, written as we worked on it. This project is finished, for any current info click here.

One of the most important things which we have to decide on is "how do we want to do it?" meaning mostly in this case the practical way of building up a prototype. Below are strategies which we were implementing so far.

Industrial prototyping

Inspired by my (Algoldor's) friend Arnd we choose to go by "industrial prototyping". Simplified: get well supported and functional parts for bit of extra cash and build up the first functional prototype from them. Afterwards when the prototype is working, start to break it down part by part redesigning them or using another cheaper/more feasible variants shaping the incubator to your like, bringing the costs down. This approach seems to be bit more expensive to start with but it ensures that even less experienced contributors to the project would be able to build their functional experimental machine, having than what to work with which I think is crucial. For more info please check this page created at Techinc hackerspace by Arnd. Till we get a proper PCB design and assembled kit you need to have some certain electronic skills set to get "smoothly involved" in the project. The more easy to put together kit option should be ready for 31c3 in December 2014.

Short time goal

- 3-4 prototypes 2.1 mamut build - deadline end of April 2014

By the end of April we want to have three to four prototypes of 2.1 Mamut running in different locations so we can test in reality the design which we choose to apply both hardware and software. The aim is to measure, display and control temperature, both heating and cooling using the kit which we presented at 30c3, sharing updates through our forum and incubator mailing list, software updates especially at Github. Next step after few months of testing, reporting on the progress and summarizing of the results will be design of the PCB boards which are base for 2.2 mamut kit version. This should be due at the end of July or during August.

Current prototypes running -

- 2.1 Mamut-TechInc, Amsterdam, The Netherlands, build by Bigmac

- 2.1 Mamut-Tamna, Gasiri, Jeju, South Korea, build by Algoldor

Medium term goals

- PCB and kit design 2.2 Mamut and 2.3 mamut - summer till winter 2014

After few months of testing of the first prototype 2.1 mamut we will design printed circuit board (PCB board) which will be the core of our experimental incubator kit - 2.2 mamut prototype/model. This one will be assembled and tested for two or three months, aiming to have all the bugs out by the end of September or October 2014. Once this prototype is debugged and functional, latest by the end of November 2014, it will become 2.3 mamut, final version of the "2" series and it will be ready for presentation at 31c3 in Hamburg. The project will be funded by crowdsourcing campaign.

Suggestions for this prototype are:

- optimize the use of current Arduino outputs

- bring down the price and safe space by using arduino nano (~$3) or arduino micro

- include NRF24L01 2.4Ghz transceivers (~$1) for remote communication

- create and apply design of PCB, possibly one for the "brain" and separate for the "relay or H-bridge" module, preferably all on one board

- the type of relays used (mechanical or opto-relays) and/or H-bridge has to be decided

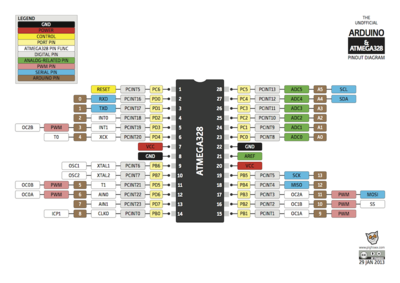

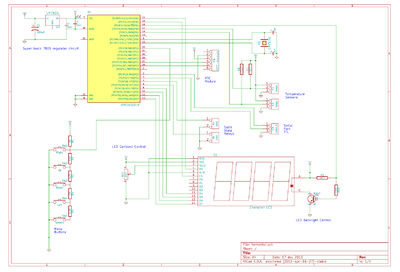

An overview of pins used for 2.1 Mamut

An overview of Arduino/Atmega328 pinouts

The following table then emerges:

D0: Serial RX

D1: Serial TX

D2: SSR1

D3: SSR2

D4: LCD D4

D5: LCD D5

D6: LCD D6

D7: LCD D7

D8: LCD RS

D9: LCD 'Enable' (might be optional)

D10: LCD backlight control (might be made optional)

D11: One-wire bus 1 (first temp-probe)

D12: One-wire bus 2 (second temp-probe)

D13: Free (see notes below about LCD, buttons and fan control)

A0: LCD Buttons

A1: Free

A2: Free

A3: Free

A4: I2C SDA-line for DS1307

A5: I2C SCL-line for DS1307

This leaves one digital pin free in a 'plain and simple way' of connecting two SSR's and two temperature-probes. We could free up two digital pins with the LCD, even more if we move it to an I2C-based way connecting it (saves another 2 to 3 wires, I believe), at the expense of more code/parts. As it is, it's not required for what we want to achieve with the device right now.

Mamut-TechInc uses D13 for fan control, so that if the box is at the right temperature, or idle, fans can be switched off. This is archieved by powering the Arduino from the standby 5V of a PC power supply, connecting D13 with a transistor to the soft power switch (pull down to ground = turn on), and switching the power supply on and off. This fan control is present in the current code.

Summary of the second generation development

The second generation fullfilled the need for testing the central unit with sensor attachements, running our code on it and sharing and updating it by Gihub. The heating and cooling function, especially the later was not functioning very well in our hardware setup based peltier system switched on/off by relay's. Because of these issues which consumed lots of time and financial resources, we have decided to focus in the third generation on the central unit, attched sensors and code, this being our priority number one. The hardware applications as an incubator chamber, type of heating and cooling, relay or H-bridge switching on/off setup should be discussed for each prototype build.