Experimental incubator - news: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

At the moment the most up to date info is at the top of the page, have fun! | At the moment the most up to date info is at the top of the page, have fun! | ||

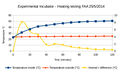

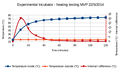

===='''Prototypes running, PCB preparations 6/7/2014 (FAA)''' ==== | |||

This is just a short update on the progress. The incubators were tested for the past month or so. In both Marcel's and my the cooling is still the issue, there were several problems with the peltiers which should be noted - some of the modules broke down. Marcel suggests to use CPU designed [http://www.tomshardware.co.uk/forum/282844-29-peltier-water-cooling water cooling system] on the hot side of the peltier. In my case [[User:Algoldor|Algoldor]] I've been making nattō heating up to 42-43°C for over 32 hours, all going well but I've to report that the heatsink got really hot, bit dangerous I would say with my current establishment, I should rebuild the heating/cooling unit enclosure. | |||

At the moment we are preparing for the PCB version of 2.2 mamut tamna. When Arnd is back from his holiday we hope to progress. I'm thinking about talking to the people from the [http://www.seeedstudio.com/depot/ Seeedstudio] in China, Shenzhen if they would be interested in helping with the PCB prototype finalization and hopefully after debugging put it online to their store as a kit. Anyway we will see about it. | |||

That would be all for now, so the plan for the next month and a bit is mostly improving the cooling of the peltiers for better cooling performance and progressing on designing the PCB prototype of 2.2 mamut tamna. | |||

Sincerely from Jeju, | |||

FAA | |||

Revision as of 07:15, 6 July 2014

At the moment the most up to date info is at the top of the page, have fun!

Prototypes running, PCB preparations 6/7/2014 (FAA)

This is just a short update on the progress. The incubators were tested for the past month or so. In both Marcel's and my the cooling is still the issue, there were several problems with the peltiers which should be noted - some of the modules broke down. Marcel suggests to use CPU designed water cooling system on the hot side of the peltier. In my case Algoldor I've been making nattō heating up to 42-43°C for over 32 hours, all going well but I've to report that the heatsink got really hot, bit dangerous I would say with my current establishment, I should rebuild the heating/cooling unit enclosure.

At the moment we are preparing for the PCB version of 2.2 mamut tamna. When Arnd is back from his holiday we hope to progress. I'm thinking about talking to the people from the Seeedstudio in China, Shenzhen if they would be interested in helping with the PCB prototype finalization and hopefully after debugging put it online to their store as a kit. Anyway we will see about it.

That would be all for now, so the plan for the next month and a bit is mostly improving the cooling of the peltiers for better cooling performance and progressing on designing the PCB prototype of 2.2 mamut tamna.

Sincerely from Jeju,

FAA

Two functioning prototypes running for sure 13/6/2014 (FAA)

For the last three weeks or so Marcel and me Algoldor have been testing the device. In Marcel's case the machine is complete, heating, cooling and automatically switching between these two functions (of course detecting the temperature too). In my case I've to switch manual so far, otherwise fine. The info about both projects was updated under the 2.1 Mamut-Tamna prototype which dedicated to the machine which I'm building up here in South Korea. Also the Experimental_Incubator/ei_prototype_designing were updated a bit especially uploading electronic schematics made by Arnd. Just quick conclusion now, both Marcel and me can heat well but the cooling is an issue and it should not be because Lar's prototype which is very similar by power and design (we used it as a blue print) is being able to go down to 8°C with over 25°C outer temperature, we manage max 4-5°C drop compared to the external temperature.

The next step is design of the PCB board prototype which we are starting to discuss with Arnd in lead.

Sincerely from Jeju,

FAA

- Two prototypes updates

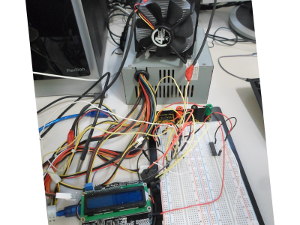

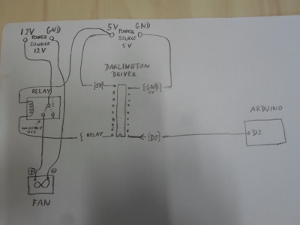

Kasiri, South Korea prototype nearly done (FAA) 3/4/2014

Here are two pictures of the circuit which I'm now testing. It is composed from Arduino (running our latest sketch updated by Marcel), darlington driver (ULN2803) to multiply the signal and the relay (JS1-5V-F) to switch on the fan which runs on 12 V delivered by standard PSU. I'm using the fan instead of the peltier, in this case it is digital 2 instead of cooling function. So far so good, next step is to connect also the peltier (60W), for now it will allow just for heating because I'm missing H-bridge.

Next step is to build up the incubator chamber and set up the hardware in a more lasting manner, but for first few days or week I will probably have things mostly on breadboards.

Sincerely,

FAA

Experimental Incubator Mailing list created!

we have a new mailing list dedicated especially to the experimental incubator project. Many thanks to Steffen who made it happen!

incubator@lists.foodhackingbase.org

If you like to subscribe please send an email to

incubator-subscribe@lists.foodhackingbase.org

and confirm your request when you receive the "confirmation email".

Welcome to this communication media, I will post more tomorrow when I hope most of us are in, but if you could start to think about recapitulating what you have done so far on the variety to this topic related project and summarize it that would be lovely :-)

Sincerely from Jeju,

FAA

PS Please let know the people who you think should know about it, thanks!

Experimental Incubator 30c3 talk video recording

Here is a link to our talk on "Open source experimental incubator build up", call for participation which we gave with Arnd (and with support of Lars) at 30c3. It covers the topic more or less, well have a look if you like

"Production" code uploaded to Github 4/2/2014

A new version has been uploaded to the github which has basic functionality: heat to temp, cool to temp, keep at temp; show time elapsed.

https://github.com/foodhackingbase/incubator

Button function: SELECT resets time; LEFT steps through the modes; UP and DOWN change target temperature; RIGHT stores the settings in EEPROM, so the program will continue after a powerdip.

Code uploaded to Github 19/1/2014

Here is the link to the code which is now uploaded to the Github

https://github.com/foodhackingbase/incubator

thanks to Lars and others from WarpZone for sharing and of course Arnd for the coding.

At the moment the code allows to measure temperature directly after switching on the Arduino, nice and simple. Not sure what else it is ready to do. Next step should be setting up switching the peltier heater on through relay, 39-43C would be fine.

Prototype tested in TechInc 12/1/2014

Here is short youtube video where we tested the Experimental Incubator prototypes which we put together during the same evening in TechInc, many thanks to Arnd for supervision and help!

https://www.youtube.com/watch?v=Z3-HGkqWRvg

What pins belong to what (before 1/2014)

Here is just a link to the info which Arnd made in preparation for 30c3, you can clearly see what pins are doing what

http://wiki.techinc.nl/index.php/Fermentation_controller#An_overview_of_pins_used

Under Arnd's supervision I was able to do all the necessary soldering by myself, putting together therefore one functional prototype, testing it later - it was doable.

An overview of pins

D0: Serial RX D1: Serial TX D2: SSR1 D3: SSR2 D4: LCD D4 D5: LCD D5 D6: LCD D6 D7: LCD D7 D8: LCD RS D9: LCD 'Enable' (might be optional) D10: LCD backlight control (might be made optional) D11: One-wire bus 1 (first temp-probe) D12: One-wire bus 2 (second temp-probe) D13: Free (see note below about LCD and buttons)

A0: LCD Buttons A1: Free A2: Free A3: Free A4: I2C SDA-line for DS1307 A5: I2C SCL-line for DS1307